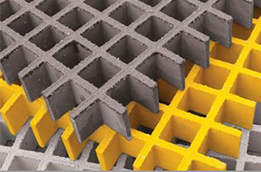

Advantages of ALPINAGRATE Gratings

1. Corrosion and Chemical Resistant

Corrosion is a major problem within industries such as chemical, steel, food and beverage, water and wastewater, power- the list goes on. ALPINAGRATE Gratings are particularly designed to provide safe, long- lasting, economical and worry- free solutions in environments where chemicals and other corrosives attack metal, wood and similar materials. Depending on the enviroment, resins sucha s orthophthalic polyester, isophthalic polyester, vinylester or phenolic may be used in the construction of our ALPINAGRATE products.

2. High strength – to- weight ratio

ALPINAGRATE Gratings are manufactured as a composite of continuous fibreglass strands and high quality resin. I tis integrally constructed for strength, and is less than one- half the weight of steel grating allowing easy removal for access and installation with no heavy equipment and reduced manual handling risks. Properly installed, ALPINAGRATE meets specified load requirements for steel and is more impact resistant than metal.

3. Impact resistance

The impact resistance of ALPINAGRATE FRP allows repeated deflection without permanent deformation. A certain amount of deflection can occur with loading. Unlike metal grating fibreglass has a good memory, so once the object is removed the Fibreglass Grating will fully recover to it?s original position.

4. Fire resistance

ALPINAGRATE Gratings are fire restistance. Depending on the resin type it achieves a Coass 1 flame spread rating of between 5-25 or less. Test reports are available on request. Special fire retardant requirements can be met with extra additives.

5. Ergonomic

Employees experience fatigue after standing on solid concrete or heavy non-adjustable galvanized steel platforms all day. ALPINAGRATE Gratings are excellent solution to ease the strain on the back, feet and legs of workers. Its natural slight resiliency makes it comfortable to stand on for long periods of time thus reducing worker fatigue. This can be improved upon by inclusion of our plastic inserts to create further allowable deflection.

6. Slip-resistant

Slips and falls are a major hazard in many industries causiing injuries and lost work days. ALPINAGRATE Gratings are available with a concave or gritted surface, both offer outstanding slip resistance in wet and oily environments and have consistently reduced slips and falls in industrial facilities.

7. Life Span

More than 30-40 years of useful life is guaranteed for ALPINAGRATE Gratings.

8. Maintenance Free

Install it and forget about it. ALPINAGRATE is easy to clean. Its open mesh permits debris to fall through the grating panel preventing a hazardous build-up on the walking surface. It is corrosion resistant ant the colour remains fast due to it is ultraviolet resistant properties.

9. Safety

ALPINAGRATE NON – CONDUCTIVE properties make it ideally suited for electrically hazardous locations, acting as an inslulator. Its NON- MAGNETIC propertis allow the grating to be used in sensitive installations where the inherent magnetic properties of metal grating will prove problematic and dangerous. NON-SPARKING ALPINAGRATE Gratings are ideally siuted for those installations where combustible gases may be present and accidental droping of tools onto the steel grating may produce sparks.

10. Cost effectivenes

Initial purchase cost of FRP Grating compares favourably with steel grating but the real saving is made on the superiour life expectancy and zero maintenance costs. Also installation costs are usually less than that of steel grating.

Any Colour Of Your Choice

The moulded-in colour is made by even fixing of pigment and resin and will not fade or require painting.